Real science

James Reid on how bicycles work | Issue 17 | 2020

Suspensions, springs and hydraulic dampers combine to make it hard to fall off a mountain bike.

How do mountain bikes work?

Satisfied with my earlier explanation of how bicycles work (for which, see issue 17 of RE:), my daughter, now seven years old, has a follow-up question. “Why doesn’t Uncle Matt fall off his mountain bike?” (Uncle Matt does everything from gnarly downhill in the Rocky Mountains to alpine single-track in the Himalayas.)

Here is my short answer (for the attention span of a seven-year-old): on the front and rear wheel of Uncle Matt's bike, there are things called shock absorbers, and they let the wheels move up and down, and doing that keeps them on the ground.

Here is the slightly longer version, involving kinetic energy, hydraulics and energy dissipation.

Modern mountain bikes have front wheel and rear wheel suspensions. Gone are the days of descending a mountain with a fixed rear wheel, or ‘hard tail’. The goal of all suspension systems is to absorb bumps (or other impact forces) in order to keep the tires in close contact with the ground without adversely affecting either braking or pedalling. This is not as easy as it sounds. The capacity of a bicycle suspension system to absorb bumps—without losing your pedalling energy to undesirable ‘pedal bob’ and without causing unwanted compression of your suspension when you brake, due to undesirable ‘brake jack’—requires a delicate suspension design balance.

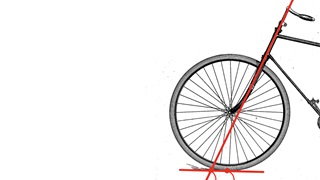

Typically, a suspension fork is used for the front wheel, and a multi-link suspension for the rear wheel. Most mountain bikes use similar front wheel suspension forks. There are many different rear suspension geometries and designs, but these would require more explanation than I have space for here.

Regardless of their design, both front and rear suspension systems require two essential elements: a spring and a damper. Often, not always, these two elements are integrated and referred to as a shock absorber.

When the wheel hits a bump, the spring allows the suspension to move upward and, once the bump has passed, to move back down to its neutral position. Without a damper, the wheel would keep bouncing up and down many times after each bump. Not what you want during a steep mountain descent! The damper absorbs and dissipates the kinetic energy from the spring; it keeps the suspension, and thus the wheel, from bouncing around uncontrollably.

Compression springs are most commonly used: a metal helical spring, for example, or an elastomeric element. The more such a compression is compressed, the more force is required to compress it. This helps to avoid ‘bottoming out’ when the wheel hits a big bump. The measure of a spring’s resistance to compression, or its stiffness, is called its spring rate.

The damper includes a piston that moves within a cylinder containing a fluid (a hydraulic fluid such as oil). As the shock absorber is compressed (when the wheel hits a bump) the piston slides within the cylinder and forces the fluid to pass through a small restricting orifice. This forced displacement of fluid converts the kinetic energy of the piston into thermal energy: the fluid heats up. In addition, the faster the piston slides (the faster or harder the wheel hits a bump), the more resistance the fluid provides and the more energy the damper dissipates; the more kinetic energy the damper dissipates, the stiffer the suspension.

By finding the right balance between the spring rate of the shock absorber’s spring and the degree of damping provided by the damper, the shock absorber of a mountain bike suspension will keep the tires in contact with the ground and, with any luck, the rider in contact with the bike.

Image (Rocky Mountain bike, Gandaki, Nepal) courtesy of Matt Reid

© Norton Rose Fulbright LLP 2025